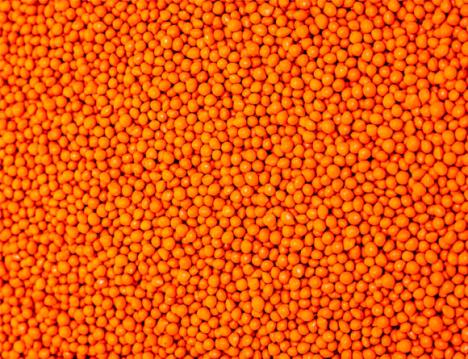

Pet food, fish feed pellets, rapeseed oil

Animal feed and seeds

Moisture measurement in livestock feed production

Implemented with:

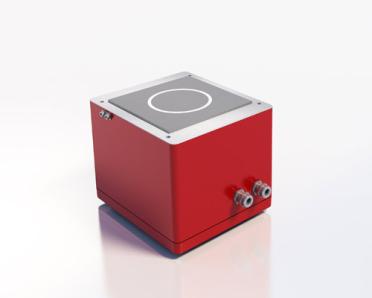

MoistureScan

Our high-precision measuring devices enable reliable moisture measurement so that you can ensure that your raw materials meet quality standards. With MoistureScan, you have control over the moisture content of your raw materials from the beginning to the end of the production process. By integrating it into your production line, you can not only improve quality, but also reduce costs and increase efficiency.

Major European animal feed manufacturers use our moisture analyzers both for checking the moisture content of incoming raw materials and for process optimization during production. They are also used for the final inspection of the finished pellets.

Discover the versatile use of MoistureScan in animal feed production!

Moisture measurement in alfalfa (alfalfa, snail clover)

Implemented with:

MoistureScan

When animal feed is produced from the nutritious plant alfalfa, it is crucial that the moisture of the individual stalks is measured and that the moisture in the bales is approx. 10-15%.

Our moisture meter enables precise measurement of moisture directly in the process before loading. This allows you to ensure that your alfalfa bales have the optimum moisture levels to minimize the risk of spontaneous combustion and maximize the quality of your feed.

Rely on our moisture meter to control the moisture of your alfalfa bales and make your feed production more efficient and safer.

Moisture measurement in the production of pet food

Implemented with:

MoistureScan

In pet food production, you have the opportunity to control the moisture of your extruded products with precision.

Our MoistureScan is used at the cooler exit to perform a final inspection before packaging. The measuring head is seamlessly embedded in the container wall at the transfer point of two chain conveyors, which means that the product flow is not affected and special built-in devices are not required.

With just four different calibration curves, the entire product range, consisting of different shapes, colors, and recipes, can be measured to ensure the different moisture limit values.

Discover the future of moisture measurement in pet food production with our MoistureScan to maximize the quality of your pet food and optimize your production processes.

Moisture measurement in the production of fish feed pellets

Implemented with:

MoistureScan

Thanks to precise moisture measurement with MoistureScan, you can ensure that your fish feed has the optimum moisture levels to promote fish health and growth.

Two of the world's leading fish feed producers rely on our moisture meters to check the moisture content of their products.

The fish feed they produce for various fish species is supplied to aquacultures around the world.

Discover the future of fish feed production with precise moisture measurement from MoistureScan!

Moisture measurement in rapeseed oil production

Implemented with:

MoistureScan EX

Rapeseed is used to produce vegetable oil as food, as animal feed or for the production of biodiesel. Our MoistureScan measuring system is used successfully in German and European plants of major international manufacturers to increase the quality and efficiency of production.

The moisture of the rapeseed in the production process is measured both in the silo before extraction and after the press when the residual moisture is measured on the rapeseed cake. Special EX-protected versions (zone 20) are used, which also work safely in potentially explosive environments. With our measuring system, you can ensure that your rapeseed has the optimum moisture values to maximize the quality of your vegetable oil, animal feed, or biodiesel.

Discover the future of rapeseed processing with the MoistureScan and rely on our precise moisture measuring devices to increase the efficiency of your production and meet quality standards!

Moisture measurement in the production of sugar beet seed

Realized with:

MoistureLab

In the production of sugar beet seed, the seed is coated with a special organic seed coating material to ensure that it can later absorb sufficient moisture for germination. Plant protection products are also applied to the material coating. After production, the sugar beet seed is stored before it is sown in the field. During this storage, it is crucial to prevent premature germination of the seed.

With the MoistureLab, you can monitor the moisture content of your sugar beet seed before storage and ensure that it is stored under optimal conditions. Thanks to precise moisture measurement, you can minimize the risk of premature germination and maintain the quality of your seed.

Rely on the MoistureLab to increase the efficiency of your sugar beet seed production and maximize the quality of your seed by always monitoring the moisture in seed production.