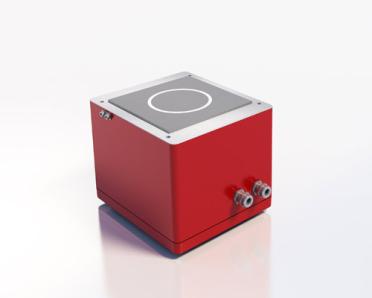

MoistureScan series

Inline moisture measurement of bulk materials

Immerse yourself in the future of production control with our density-independent moisture measurement systems!

Seamlessly embedded in your production flow, our system provides continuous monitoring of your product's water content, without any heating. How? By using microwaves that measure precisely and reliably in fractions of a second - regardless of density, weight, color, or surface.

What makes our system so unique? It enables extremely accurate and fast measurement, inspecting both core and surface moisture. Thanks to our long-term stable process, you can be sure that your measurements will remain consistently accurate.

The automated process control makes handling our system child's play. Thanks to simple calibration and extensive evaluation options, you are always in control of your production. And if you do need assistance, we offer you first-class online support.

With our measuring system, you not only minimize waste, but also reduce your energy costs - a real benefit for your company. Experience the future of production with us and increase the efficiency and quality of your products!

Features at a glance

Microwave-based measurement technology

- Very accurate and fast measurement

- Control of core and surface moisture

- Long-term stable method

- Measurement independent of density, weight, color and surface of the product

Optimized

process

- Automated process control

- Up-to-date information on process control

- Fast and timely detection of faults

Simple

handling

- Measurement can be tracked on monitor

- Simple calibration

- Extensive evaluation options

- Online support

Effects on

your production

The devices in the MoistureScan series

- prevent costly production downtimes

- enable product quality to be achieved more quickly

- minimize rejects

- reduce costs due to complaints

- reduce energy costs

- optimize use of personnel

For varied conditions of use

MoistureScan

Continuous in-process moisture measurement

Fast and reliable inline definition of relevant process parameters is essential to optimum production. And the process parameter moisture is important in many areas of industry.

The task

Precise and fast measurement of the product moisture during the process in order to monitor and control the production process. This ensures high product quality.

The solution

The integrated moisture measuring system MoistureScan continuously measures the moisture of the product irrespective of density and sends the measurement results to the process control system.

MoistureScan XT

For temperatures up to 140 °C

In some production processes, temperatures of more than 100 °C occur at the outlet of a dryer, behind a press or a roasting oven. The MS XT sensor can withstand temperatures of up to 140 °C.

The task

A customer would like to measure the product moisture at the dryer outlet. The temperatures there fluctuate between 70 °C and 130 °C. The customer would like to improve the production process with precise measurement of the moisture up to almost 100 °C at this point to enhance the quality of the product and save energy.

The solution

Thanks to its components made of steel and ceramics, the patented design of the MoistureScan sensor from Döscher Microwave Systems permits temperatures up to 140 °C.

MoistureScan EX

Explosion-proof for EX zone 20

The MoistureScan EX fulfills all safety requirements imposed by law on devices for use in potentially explosive atmospheres.

The task

A manufacturer of fruit gums relies on fast moisture measurement in the process for conditioning the corn starch used. Corn starch is explosive and all plant sections containing the product are classified as zone 20.

The solution

MoistureScan EX is equipped with a sensor surface on the product side that is suitable for installation in potentially explosive atmospheres. The measuring head is approved for use in zone 20. The other components of the measuring device are designed for zone 22.

MoistureScan CER

Ceramics provide lasting protection against wear

Ceramic provides lasting protection against wear. Another special solution for a product process under demanding conditions.

The task

A customer processes very abrasive materials and the product also contains quartz sand. The sensor head must withstand this extreme stress over a long period.

The solution

The parts of the sensor head that come into contact with the product are made of ceramic. The required high level of wear protection is guaranteed.

Simple operation

Moisture curve

Software

The devices in the MoistureScan series are operated using intuitive software. All the steps you need are easy to perform.

The measurement results are clearly displayed.

Calibrations can be easily performed and visualized.